BIESSE STREAM B1 Edge Banding Machine

Technical data:

Media:

Artr.-No.: 4681

Make: BIESSE

Type: STREAM B1/10.5

Year: 2010

Mach.-No.:

Edge banding machine in industrial design

* AXIS CONTROLLED

* GLUING WITH EVA OR PUR ADHESIVES

* 2 USE-CONTROLLED GROOVE/FOLD/PROFILE MILLING UNITS IN

POST-PROCESSING

* EQUIPMENT FOR PVC, VENEER; OR SOLID

WOOD STRIP PROCESSING

Technical specifications:

min. workpiece width 65 mm

min. workpiece length 150 mm

max. workpiece width 3,200 mm

max. workpiece length 3,200 mm

panel thickness 10 - 60 mm

edge band thickness 0.3 - 20 mm

feed speed adjustable 10 - 25 m/min. The actual working speed depends on the respective use of the corresponding processing units.

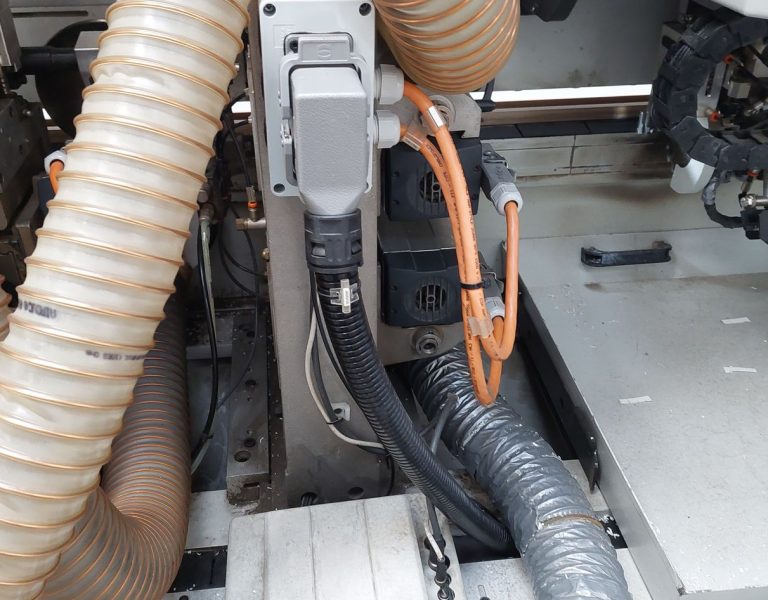

Top pressure system with double composite belt

Insertion device for narrow parts available, currently not installed

Equipment:

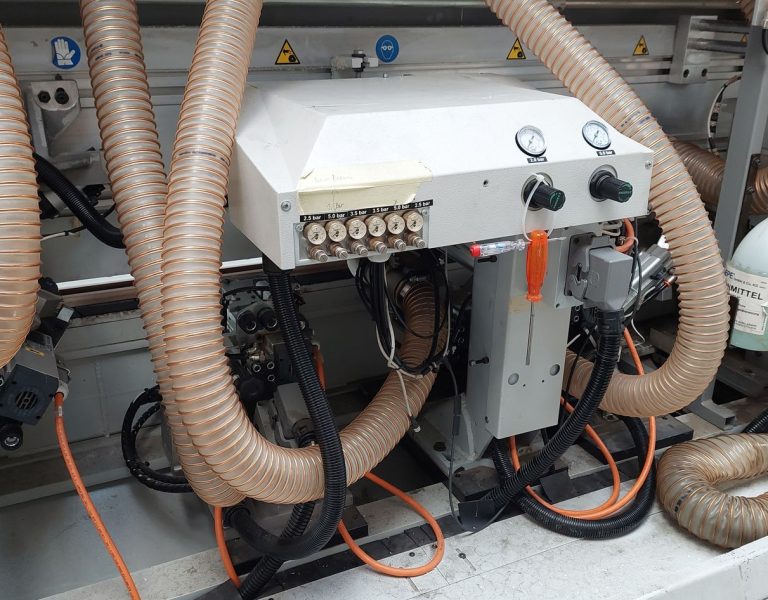

Anti-Stick-Solvent agent application

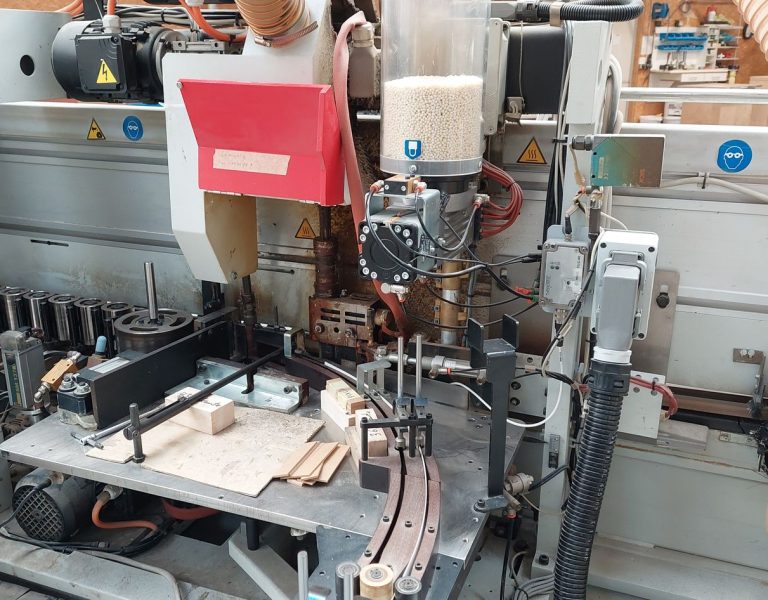

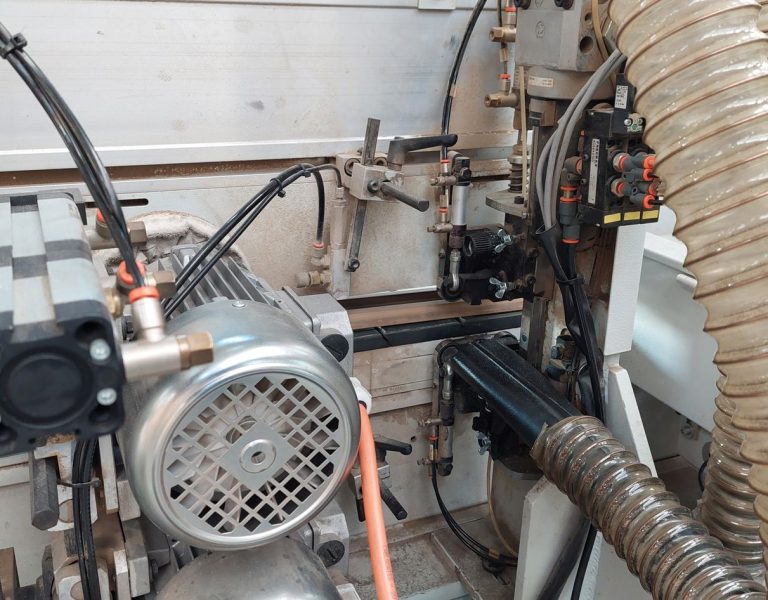

Pre-milling unit with 2 motors each 3,5 KW

Speed 9,000 rpm

NC controlled tracing shoe for controlling the removal via

NC axis

Edge gluing station with granulate pre-melter for

processing EVA hot melt adhesives

PU unit for processing PUR hot melt adhesives available

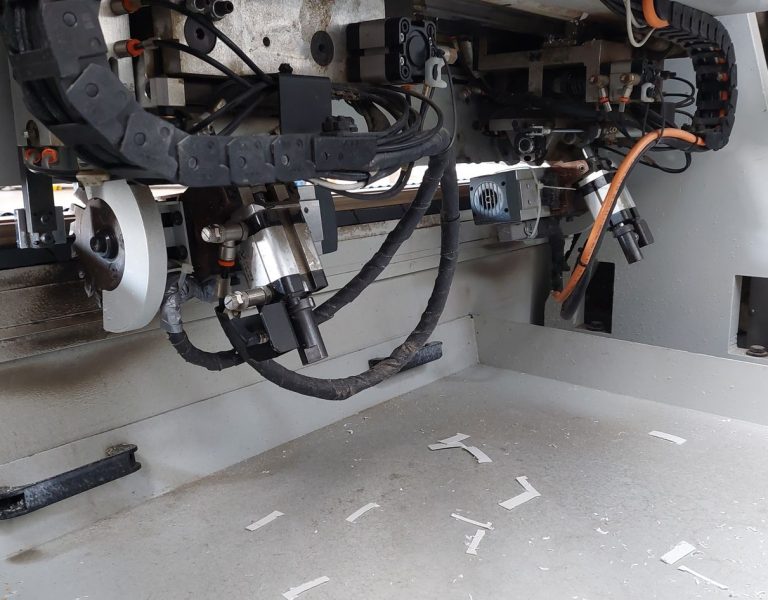

Pressure zone with 1 main pressure roller and 6 pressure rollers

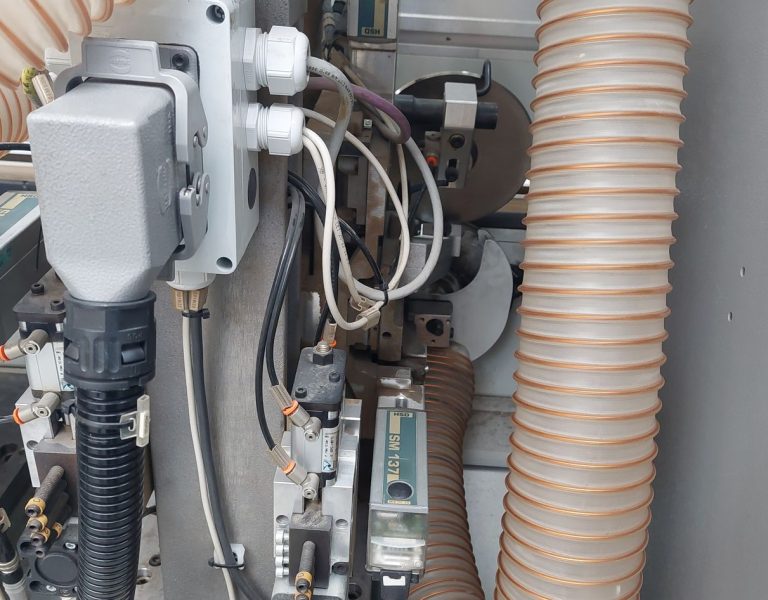

End-trimming unit IP90-S

mounted on the top pressure, with 2 motors of 0.65 KW,

adjustable from straight to bevelled caps via program

Tracing shoe for 3 independently adjustable stops for adjusting the Y feeler shoe

Speed 12,000 rpm

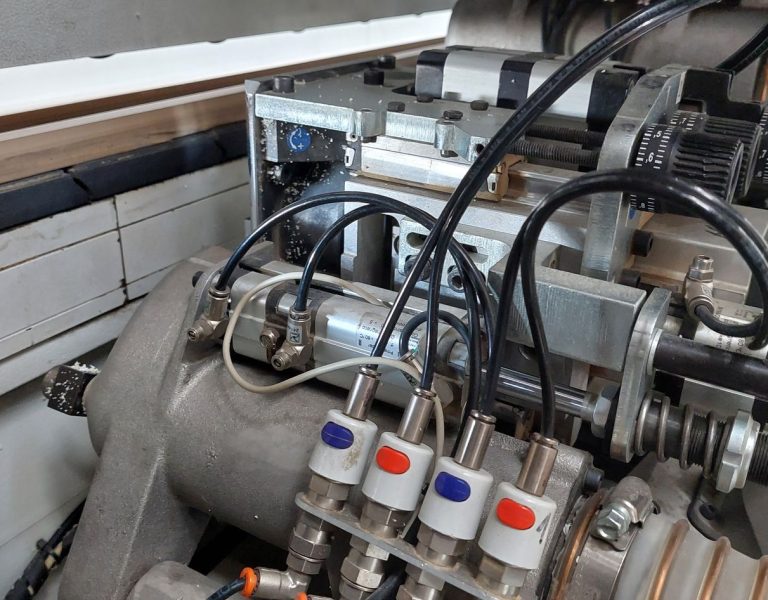

Flush milling unit RS10

with 2 one above the other horizontal motors of 2 KW each

Speed 12,000 rpm

Pneumatic device for second working position

Pos 1 for ABS/PVC edges

Pos 2 for veneer/solid wood edges

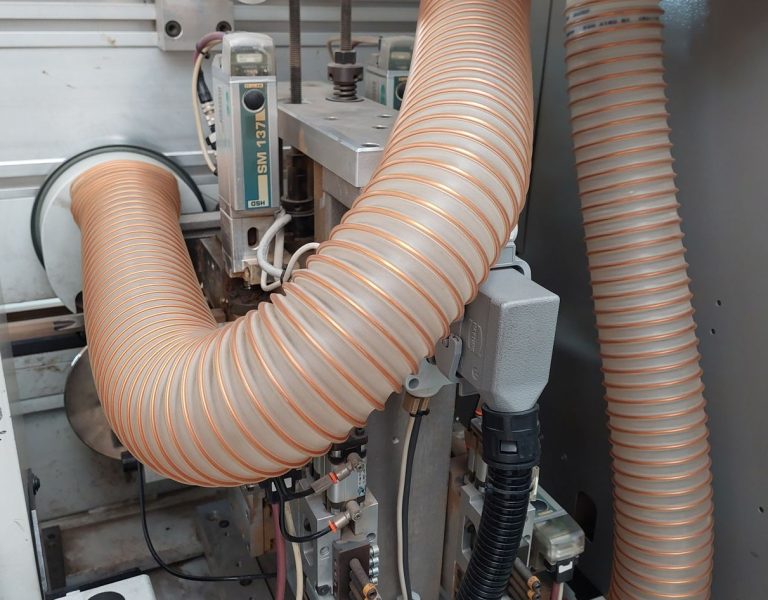

Chamfer milling/radius milling unit RF40

with axis adjustment via program

Unit suitable for multi-tools

Motor power 0.65 kW, 12,000 rpm

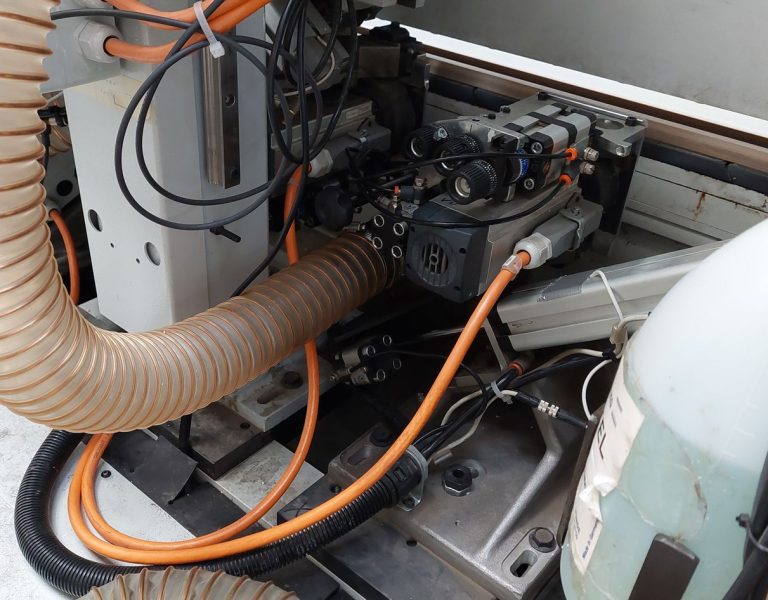

Form milling/copy milling unit AR34

with 4 motors of 0.65 KW each, 12,000 rpm

Edge thickness 0.3 - 3 mm

for fine milling/corner copying

4 pneumatic fixed points controllable via program

for processing 3 thin edges and 1 thick edge

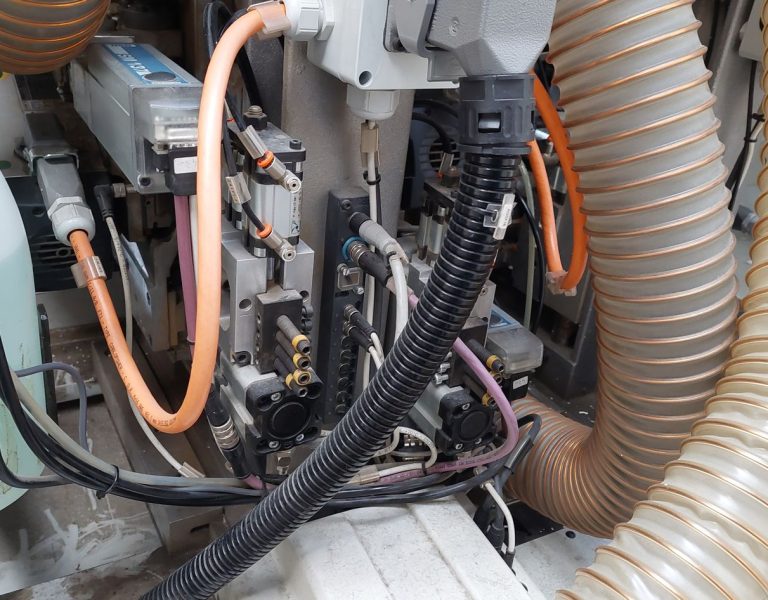

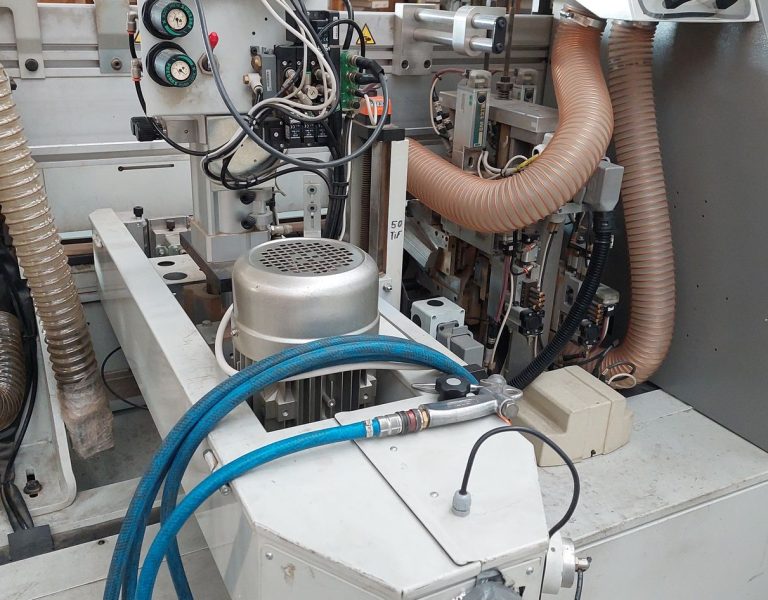

2 pcs. Groove / rebate / profile milling units FB 30

Motors 4.5 kW, units can be manually swiveled 0 / 90 degrees,

operation controlled

Speed 12,000 rpm

Tool diameter 125 mm

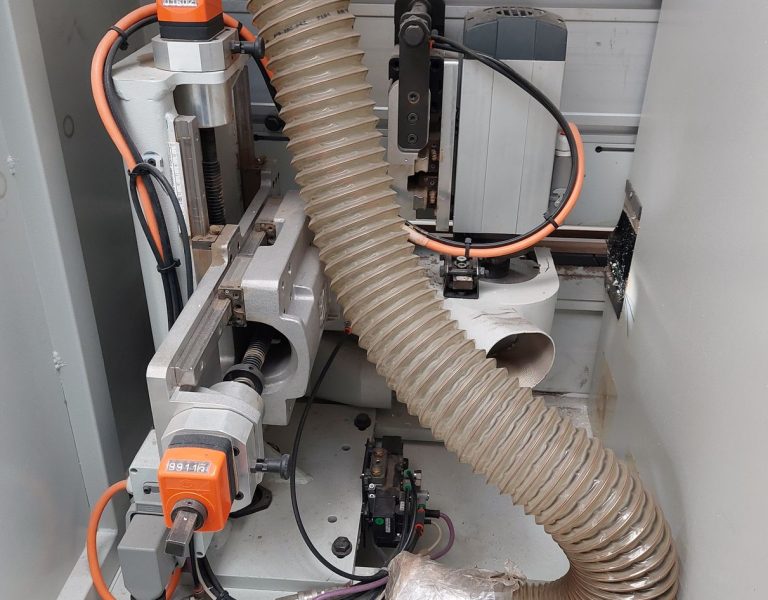

Profile scraper unit RB40

For reworking ABS, PVC & PP edges

suitable for multi-profile tools

Radius max. 3 mm

Automatic switching to 4 different positions using

servo drives

Flat scraper unit RC20

For removing glue residues along the glue joint

Edge sanding unitFor sanding the edge surface of veneer or solid wood edges

manually adjustable

Sanding belt size 2,500 x 120 mm

Oscillating buffing unit SZ30

Motors 0.37 KW