KUPER FL/INNOVATION Veneer Splicing Machine

Technical data:

Media:

Artr.-Nr.: 4714

Make: KUPER

Type: FL/INNOVATION

Year: 1999

Mach.-No.:

For splicing smooth veneers in the thickness range of

approx. 0.3 - approx. 2.5 mm.

Specially developed for bonding veneers exposed to high temperatures and tensile loads during further processing (e.g., in wrapping and membrane press technology).

The veneers are bonded together at their butt joints using urea glue. The glue is applied either with the Kuper KLM veneer pack gluing machine or by the glue applicator integrated in the FL/INNOVATION.

Specific Features:

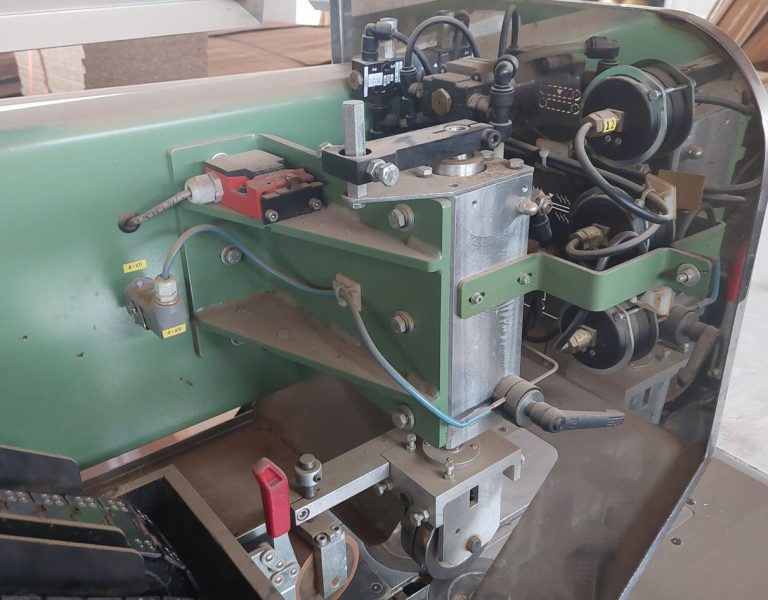

- Integrated glue dispenser

- Sturdy steel frame construction

- Durable PUR coating

- Pre-feed via discus discs

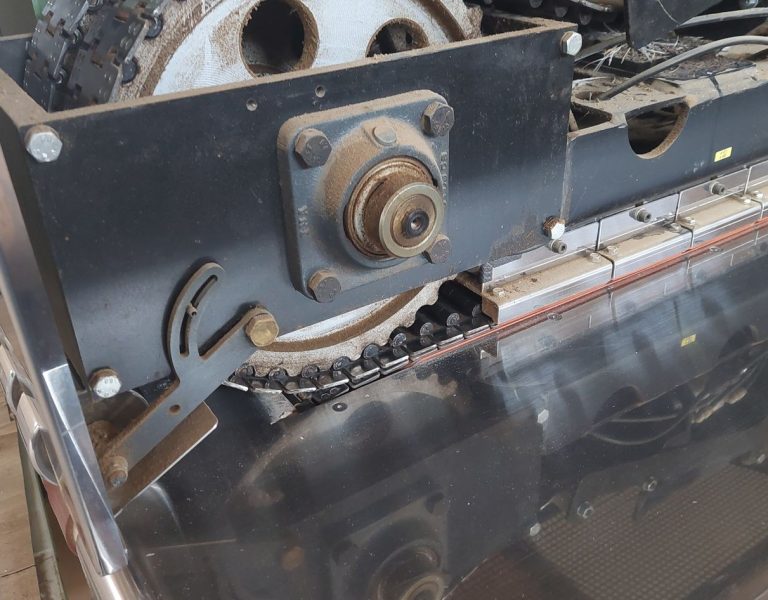

- Stainless steel chain conveyor

- Chain conveyor via robust spur gear drive with cardan shafts

- Extra-long, individually temperature-adjustable heating zone

- Pivoting commander housing for all important control and operating elements

- Intermediate conveyor at the infeed for shorter veneer strips

Frame projection: 1000 mm

Veneer thicknesses: approx. 0.3 - 2.5 mm

Veneer lengths: from approx. 300 mm

Veneer strip widths: from approx. 45 mm

Feed speed: approx. 20 - 50 m/min.

Heating zone length: 1200 mm

Heating temperature: max. approx. 220 °C

Operating voltage: 400 V, 50 Hz, 3-phase

Total connected load: approx. 9.3 KVA

Average power requirement: approx. 5 kW

Air consumption: approx. 5 NL/min. at 6 bar

Space required: 2370 x 1960 x 1470 mm