HOMAG KAR330/8/A20 Edge Banding Machine

Technical data:

Media:

Artr.-Nr.: 4709

Make: HOMAG

Type: KAR330/8/A20

Year: 2011

Mach.-No.:

Workpiece dimensions

Width (D=8-22mm) min. 60 mm

Width (D=23-60mm) min. 100 mm

Thickness min. 8(12), max. 60 mm

Feed rate 18 – 25 m/min

Working height 950 mm

Workpiece projection 30 mm

Roll material = 0.3 – 3 mm

Strip material = 0.4 – 20 mm

Extraction capacity approx. 5,480 m3/h

Compressed air consumption approx. 975 Nl/min

Electrical connection value approx. 34 kW

Rated current: 63 A

Brief description of the units

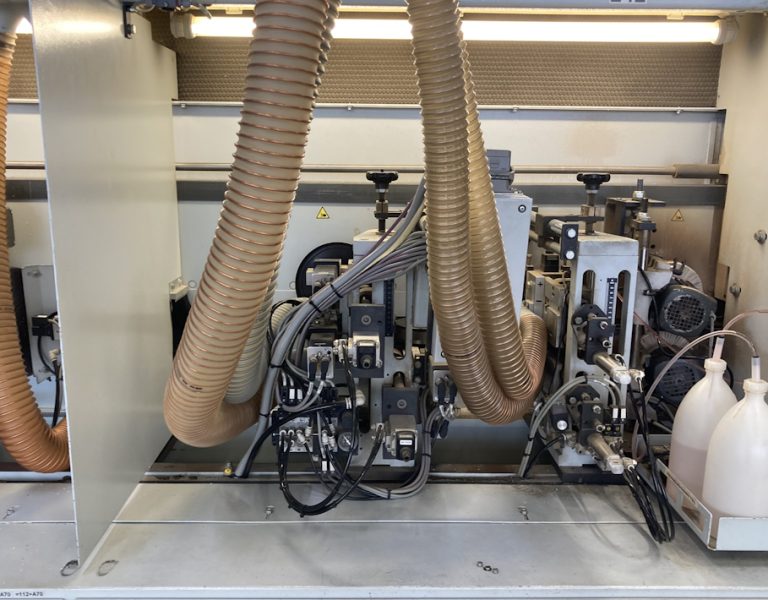

1. Automatically adjustable infeed ruler (extended by 500 mm)

a. Sliding carriage, foldable

2. Feed device (2 rollers) (electrically pneumatically fold up)

3. Spray unit (release agent top/bottom)

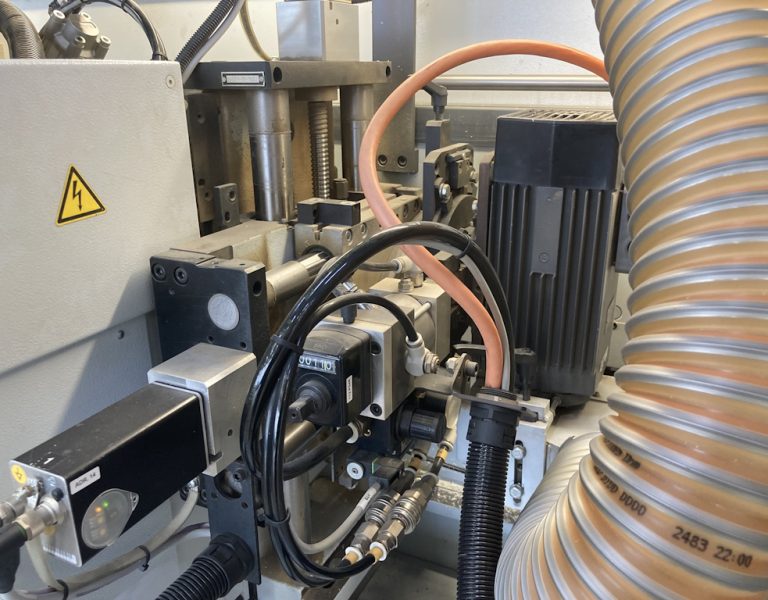

4. Joining milling unit, (2 motors, left/right), slide joining milling cutter 125x63x30

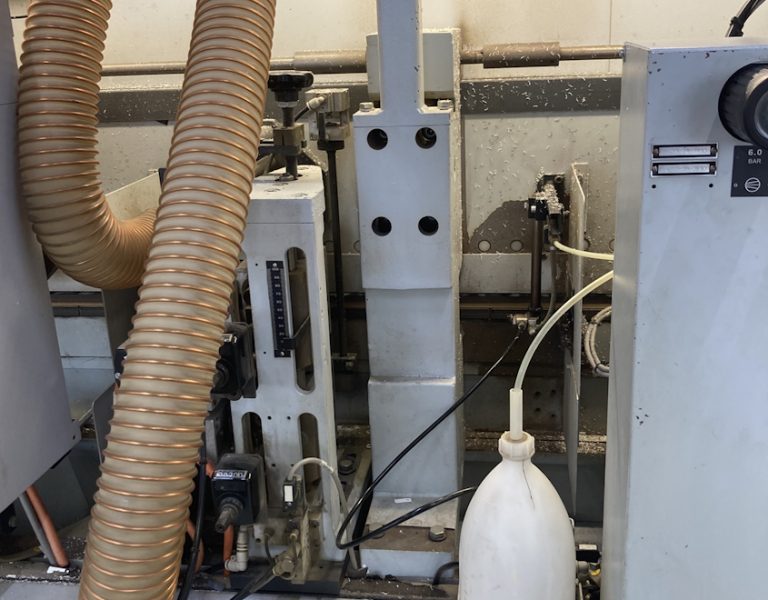

5. Gluing part A20 extended

a. Workpiece preheating

b. Quickmelt application unit, changeable (with melting unit), dosing slide for cleaning (max. 12 kg/h)

c. 2-way edge magazine

d. Pressure rollers (1x D150, 6x D70)

e. Wetting 1. Pressure roller (release agent)

6. Spray unit (coolant, antistatic)

7. Cutting unit HL84 chamfer/straight (pneum. adjustment)

8. Pre-milling unit BF20 [ (flush milling top/bottom), (pneum. adjustment)

9. Spray unit (release agent application)

10. Form milling unit FK11 top/bottom, interchangeable heads chamfer/radius

11. Universal milling cutter UF11 controlled, currently: 4 mm grooving saw + rebate head

12. Profile scraper PN21 automatic chamfer/radius

13. Finishing unit FA11 top/bottom

a. Glue joint scraper

b. Cleaning agent application

c. Buffing unit

Other:

- additional workpiece support, scissor design, max. 1,000 mm extendable

- narrow top pressure roller pitch (50 mm instead of 80 mm)

- setting up in the gap

Return ZHROS/R/O9S – Boomerang

- widening of return path to 1,100 mm

- roller strips can be lowered, support for wide parts

- roller conveyor on the outlet side with rollers

- air table across in front of the inlet